How to Make A Trampoline with All Details

Ivellios2021-07-01T07:26:24+00:00

The production of the trampoline is not too hard to explain. It’s going step by step, but the whole process is not easy, and even can be very energy-consuming. The most difficult part is to produce every single part of the trampoline with high standards.

Different manufacturers supply different quality, but the general producing procedures are quite similar. Below we are introducing the general guidelines for trampoline manufacturing.

Design – how to draw a wanted trampoline

First of all, it’s not that fast for mass production. Every product with customized requirements by customers should go with designs in the beginning. This process starts with design graphs on the computer. Though we do have standard types producing all the time, it’s very tough to work for every customer. Different customers from different countries truly have very different needs and demands.

Manufacturers need to confirm what kind of trampolines customers want, and manufacturers will have to present the design graphs for that ideas. At this time, the design team from the manufacturer you selected is very important, because they are at the first frontier that can vividly realize the designs you or your customers favor.

In another situation, purchasers or customers love to provide their own design, and they already have graphs for that. Then all that’s left to do for manufacturers is to make samples according to the design graph.

Sample & test – how to build a good trampoline

Design graph is something on paper, manufacturers have to make it into real life. Some designs can be amazing and even surprising, but the manufacturing capacity may not match. That is why the sample is important, this is the process manufacturers put the design into the real pre-mass-production stage and test if the manufacturing capacity can catch up with the designs.

This is not the whole story, we have to use different designs and raw materials for sampling, according to the customers’ requests, and sometimes we are required to test in the third-lad for the main index of certain properties, such as the max loading capacity of the jumping mat, and the corrosion-resistant level of steel pipes. If passed, it’s high time to merge into the mass production stage.

Mass production – trampoline manufacturing

Mass production stage consists of many parts to the final package:

Trampoline steel pipes

This is the first part of mass production. Most of manufacturers are using galvanized steel as raw material for the pipes, including steel legs and poles, and are sourcing from professional steel companies with certain demands such as diameter, thickness, and length, even yield strength and tensile strength as physical performance.

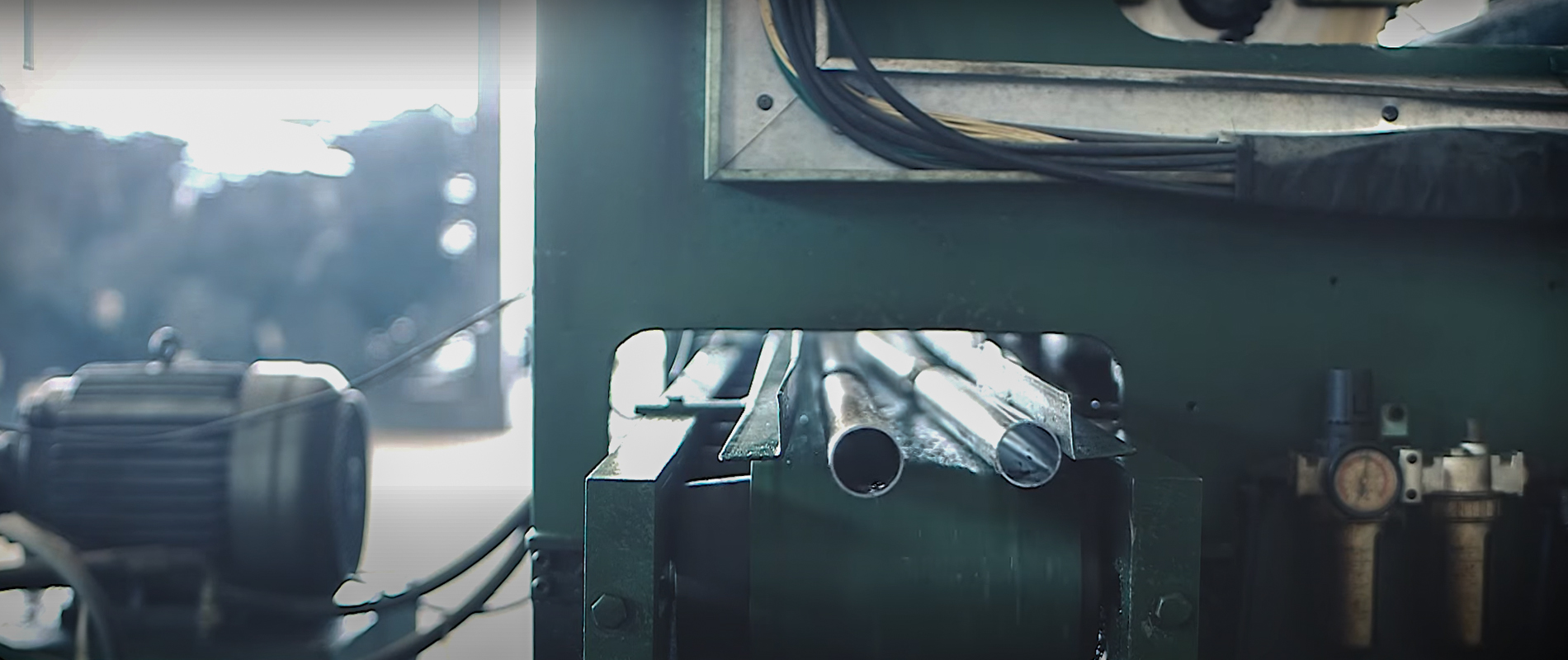

As soon as the steel pipes arrive at the factory, the production starts. Machines, at this stage, play a significant role, which are applied in the four procedures of steel pipes processing by order: cutting, bending, necking, and punching.

Jumping mat of trampoline

At this stage, it’s critical to use different kinds of PP material, whose full official name is Polypropylene. This material is widely used in many industries, but all you need to know about trampoline is that the better PP material applied, the better jumping mat is. You can identify from below five aspects: loading capacity, elongation rate, shrinkage rate, melting temperature, and environment-friendly standards.

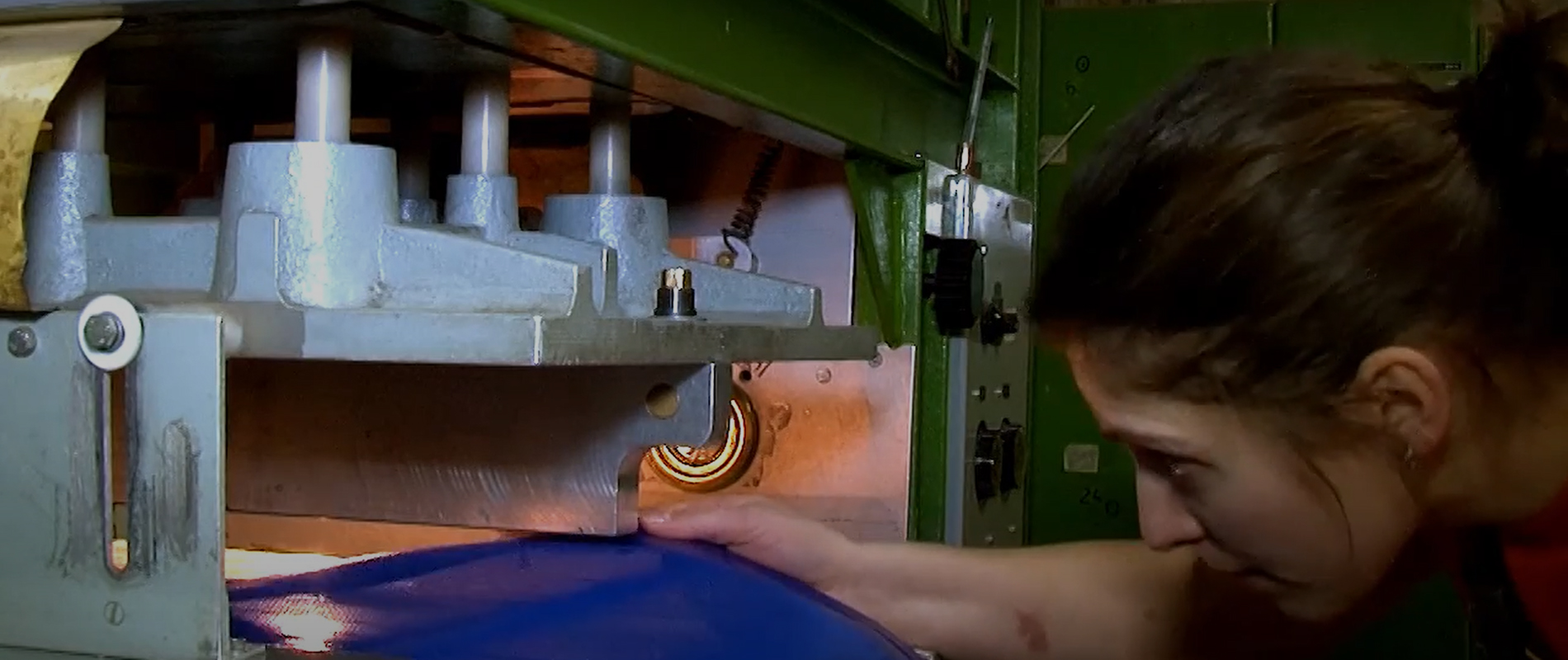

All the processing at this stage includes: tailoring and sewing with V-rings and logo printing.

Trampoline enclosure parts

PP material is also used for the enclosure, and this part includes: tailoring, edge closing, positioning lines drawing, hooks and zippers sewing. The poles are finished processing at the pipes’ part, there is little to do with it now. Just need to equip the poles with EPE foams, blister with screws, and pack all of the springs per set.

Trampoline safety pad

It’s very hard to explain clearly about the material using for safety pads since different manufacturers choose to use different materials, but it can generally conclude PVC, PE, This involves tailoring, edge sewing with webbing and elastic cord.

Package

properly settle all the accessories and parts, and manual, pack to wait for shipping.